Initial Ideation

Context

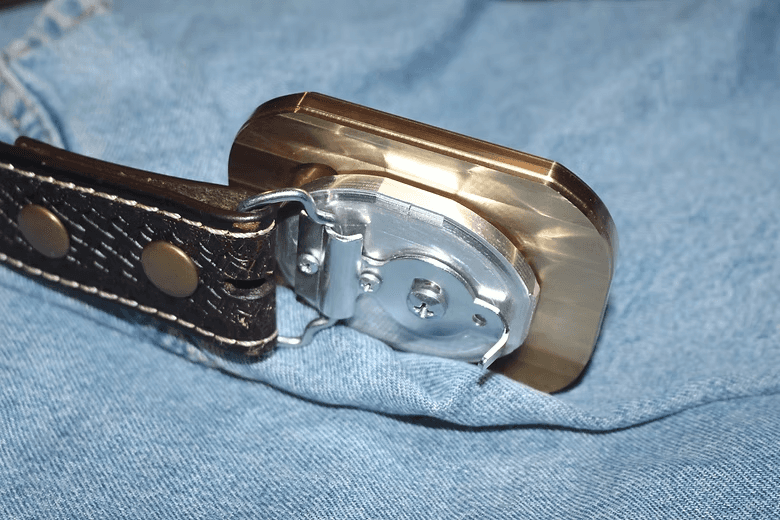

For the project, we were given no prompt. The only requirement was to make a product with a mechanical connection or interface. I was inspired by a range of ideas, but decided to expand on the idea of an interchangeable belt buckle I had worked on in the past.

Project Type:

Individual Class Project

A swappable belt buckle manufactured on CNC using brass and aluminum. The buckle designs attached to the connector using a threading mechanism.

The brass buckle design is inspired by my ethnic background and the Sierra Leonean emblem of the Coat of Arms.

The Aluminum design is inspired by Paul Frank, a childhood icon in the likes of Hello Kitty and Domo.

Key Skills:

Autodesk Fusion360, CAM, CNC Mill